ਉਤਪਾਦ ਵੇਰਵਾ

Good quality Metal Sheet and Tube Fiber Laser Cutting Machine Used in Agricultural Equipment

ਉਤਪਾਦ ਦੀਆਂ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ

Imported high precision ball screw/ rack and pinion transmission, high precision linear guide rail.

Imported servo motor driving system , imported helical gearbox.

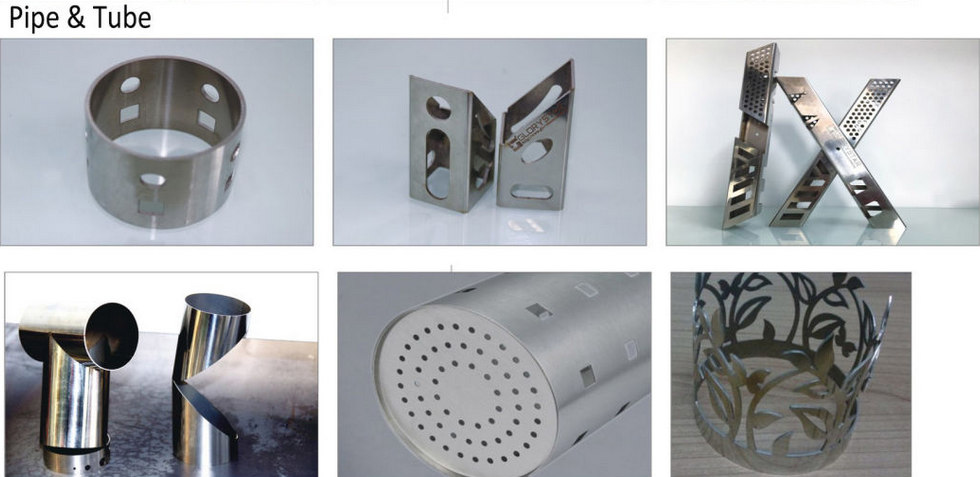

Separate cutting tube device.

Fast cutting speed, high efficiency,safe, stable performance.

Good quality Metal Sheet and Tube Fiber Laser Cutting Machine Used in Agricultural Equipment

ਤਕਨੀਕੀ ਡਾਟਾ

| ਲੇਜ਼ਰ ਪਾਵਰ | 500W-8000W(Optional) |

| ਕਾਰਜ ਖੇਤਰ | 3000 * 1500mm |

| ਕੁਲ ਬਿਜਲੀ ਦੀ ਖਪਤ | 10Kw<60Kw |

| Transmission Mode | Gear and Rack Double drive |

| Voltage and Frequency | 380V 50Hz(60Hz) |

| ਮਾਪ | 4800*3260*1750mm |

ਲਾਗੂ ਸਮਗਰੀ

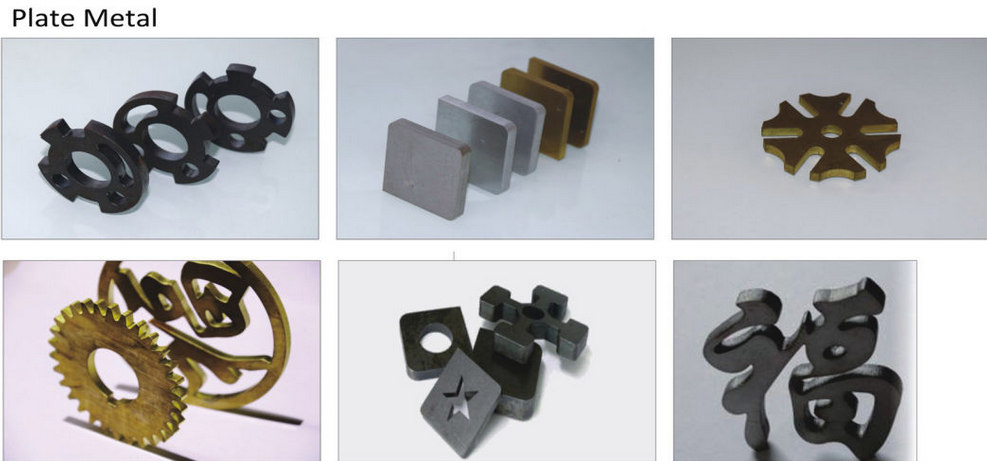

Mainly applied to all kinds of sheet metal materials with non-contact fast cutting,hollowing and punching. Such as mild steel, stainless steel, alloy steel, manganese steel,galvanized, aluminum, copper and metal pipe processing, etc.

ਲਾਗੂ ਉਦਯੋਗ

Widely used in all kinds of metal products industries such as sheet metal processing, kitchen ware and bathroom ,advertising & signs, lighting & hardware,electrical cabinets, auto parts,machinery and equipment, household appliance,elevator and precision parts processing ,etc.

ਮੁੱ Infoਲੀ ਜਾਣਕਾਰੀ

ਲੇਜ਼ਰ ਤਕਨਾਲੋਜੀ: ਲੇਜ਼ਰ ਕੰਟਰੋਲ ਫਾਲਟ ਕੱਟਣਾ

Automation: Automatic

Type for Cutting Machine: Laser Cutting Machine

Type: Metal Laser Cutting Machine

ਲੇਜ਼ਰ ਦੀ ਕਿਸਮ: ਫਾਈਬਰ ਲੇਜ਼ਰ

Cutting Acurancy: 0.01mm

ਸ਼ਰਤ: ਨਵਾਂ

Certification: GS, Ce, ISO9001, SGS

Standard: GB

Customized: Non-Customized

Material: Metal

ਟ੍ਰੇਡਮਾਰਕ: ਏ.ਸੀ.ਸੀ.ਆਰ.ਐਲ.

Transport Package: Seaworthy Plywood Case

Specification: CE SGS FDA ISO

ਮੂਲ: ਅਨਹੂਈ, ਚੀਨ

ਐਚਐਸ ਕੋਡ: 8456100090

Sample Show

| 1000W fiber laser cutting machine cutting parameters | |||||||

| ਪਦਾਰਥ | ਮੋਟਾਈ ਕੱਟਣਾ (ਮਿਲੀਮੀਟਰ) | Cutting speed(m/min) | ਗੈਸ ਕੱਟਣਾ | Cutting pressure | ਨੋਜ਼ਲ | Collimator / Focus | Remarks |

| ਕਾਰਬਨ ਸਟੀਲ | 0.5 | 30-40 | ਹਵਾ | 6 | 1.5 single layer | 75/125 | Please adjust accord to actual focal position by cutting head, all parameters for reference |

| 0.8 | 20-25 | ਹਵਾ | 8 | 1.5 single layer | 75/125 | ||

| 1 | 18-22 | ਹਵਾ | 10 | 2.0 single layer | 75/125 | ||

| 2 | 5-6.5 | ਆਕਸੀਜਨ | 3.5 | 1.2 double layer | 75/125 | ||

| 3 | 3-3.5 | ਆਕਸੀਜਨ | 0.5-1 | 1.2 double layer | 75/125 | ||

| 4 | 2-2.3 | ਆਕਸੀਜਨ | 0.5 | 1.2 double layer | 75/125 | ||

| 5 | 1.5-1.8 | ਆਕਸੀਜਨ | 0.5 | 1.2 double layer | 75/125 | ||

| 6 | 1.2-1.4 | ਆਕਸੀਜਨ | 0.5 | 1.5 double layer | 75/125 | ||

| 8 | 0.9-1.2 | ਆਕਸੀਜਨ | 0.5 | 2.0 double layer | 75/125 | ||

| 10 | 0.7-0.8 | ਆਕਸੀਜਨ | 0.5 | 2.5 double layer | 75/125 | ||

| 12 | 0.5-0.65 | ਆਕਸੀਜਨ | 0.5 | 2.5 double layer | 75/125 | ||

| ਸਟੇਨਲੇਸ ਸਟੀਲ | 0.5 | 30-40 | ਨਾਈਟ੍ਰੋਜਨ | 7 | 1.5 single layer | 75/125 | |

| 0.8 | 22-25 | ਨਾਈਟ੍ਰੋਜਨ | 10 | 1.5 single layer | 75/125 | ||

| 1 | 20-23 | ਨਾਈਟ੍ਰੋਜਨ | 12 | 1.5 single layer | 75/125 | ||

| 2 | 6-7 | ਨਾਈਟ੍ਰੋਜਨ | 15 | 2.0 single layer | 75/125 | ||

| 3 | 2.5-2.8 | ਨਾਈਟ੍ਰੋਜਨ | 18 | 2.0 single layer | 75/125 | ||

| 4 | 0.8-1.2 | ਨਾਈਟ੍ਰੋਜਨ | 18 | 2.0 single layer | 75/125 | ||

| 5 | 0.6-0.8 | ਨਾਈਟ੍ਰੋਜਨ | 18 | 2.0 single layer | 75/125 | ||

| ਅਲਮੀਨੀਅਮ | 0.5 | 20-25 | Air / Nitrogen | 8 | 1.5 single layer | 75/125 | |

| 0.8 | 15-18 | Air / Nitrogen | 9 | 1.5 single layer | 75/125 | ||

| 1 | 10-12 | Air / Nitrogen | 12 | 1.5 single layer | 75/125 | ||

| 2 | 3-3.5 | Air / Nitrogen | 18 | 2.0 single layer | 75/125 | ||

| 3 | 1-1.5 | Air / Nitrogen | 18 | 2.0 single layer | 75/125 | ||

| ਪਿੱਤਲ | 0.5 | 22-30 | ਨਾਈਟ੍ਰੋਜਨ | 12 | 1.5 single layer | 75/125 | |

| 0.8 | 13-17 | ਨਾਈਟ੍ਰੋਜਨ | 12 | 1.5 single layer | 75/125 | ||

| 1 | 10-12 | ਨਾਈਟ੍ਰੋਜਨ | 15 | 1.5 single layer | 75/125 | ||

| 2 | 2-3 | ਨਾਈਟ੍ਰੋਜਨ | 18 | 2.0 single layer | 75/125 | ||

| 3 | 1-1.3 | ਨਾਈਟ੍ਰੋਜਨ | 18 | 2.0 single layer | 75/125 | ||

| ਤਾਂਬਾ | 0.5 | 15-18 | ਆਕਸੀਜਨ | 12 | 1.5 single layer | 75/125 | |

| 0.8 | 8-12 | ਆਕਸੀਜਨ | 12 | 1.5 single layer | 75/125 | ||

| 1 | 5-7 | ਆਕਸੀਜਨ | 12 | 1.5 single layer | 75/125 | ||

| 2 | 0.8-1.2 | ਆਕਸੀਜਨ | 15 | 2.0 single layer | 75/125 | ||